Kgrs. per year raw material

k

annual parts produced

0

k

Cold deformation process of materials for the manufacture of highly technical parts designed by the customer with reduced tolerances and high demands in terms of capacity and repeatability.

The dimensional precision of the parts we manufacture by stamping is crucial to guarantee the standards of quality and reliability of the final product that the customer demands of us.

Cold deformation process of materials for the manufacture of highly technical parts designed by the customer with reduced tolerances and high demands in terms of capacity and repeatability.

The dimensional precision of the parts we manufacture by stamping is crucial to guarantee the standards of quality and reliability of the final product that the customer demands of us.

Winding process using axial shafts that allow precise calibration of the inner shape of the casing with minimum material waste.

Specialization in copper parts for both common electrical systems and vehicle inverters with electric motorization.

Use of all types of materials of different hardness, from brass or copper, through aluminium, galvanised, stainless or materials with high elastic limit. Thicknesses from 0.25 to 4 mm.

TIG and spot welding processes as an additional phase to stamping

All types of additional phases to stamping for the assembly of parts, both in manual and automated phases.

Alcohol modified degreasing process with excellent reach of surface tension level and high compliance with particle size requirements.

Winding process using axial shafts that allow precise calibration of the inner shape of the casing with minimum material waste.

Specialization in copper parts for both common electrical systems and vehicle inverters with electric motorization.

Use of all types of materials of different hardness, from brass or copper, through aluminium, galvanised, stainless or materials with high elastic limit. Thicknesses from 0.25 to 4 mm.

TIG and spot welding processes as an additional phase to stamping

All types of additional phases to stamping for the assembly of parts, both in manual and automated phases.

Alcohol modified degreasing process with excellent reach of surface tension level and high compliance with particle size requirements.

Multi-Slide axial shaft machines.

Availability of machines with initial press of different tonnages.

Mechanical presses and servo presses from 80 to 400 Tn. allow a great potential in the manufacture of all types of part

Cleaning and degreasing machines with modified alcohols in a closed circuit without environmental impact avoid mixing of materials and the adjustment of the appropriate parameters for each type of part.

Assemblies and automatisms dedicated to each specific need.

Multi-Slide axial shaft machines.

Availability of machines with initial press of different tonnages.

Mechanical presses and servo presses from 80 to 400 Tn. allow a great potential in the manufacture of all types of part

Cleaning and degreasing machines with modified alcohols in a closed circuit without environmental impact avoid mixing of materials and the adjustment of the appropriate parameters for each type of part.

Assemblies and automatisms dedicated to each specific need.

The computerised quality management system (QMS) allows us to comply with the standards based on IATF16949 and ISO14001. By analysing data and identifying opportunities for improvement, we are able to control and improve processes in order to deliver high quality products and services to our customers. qualitat als nostres clients.

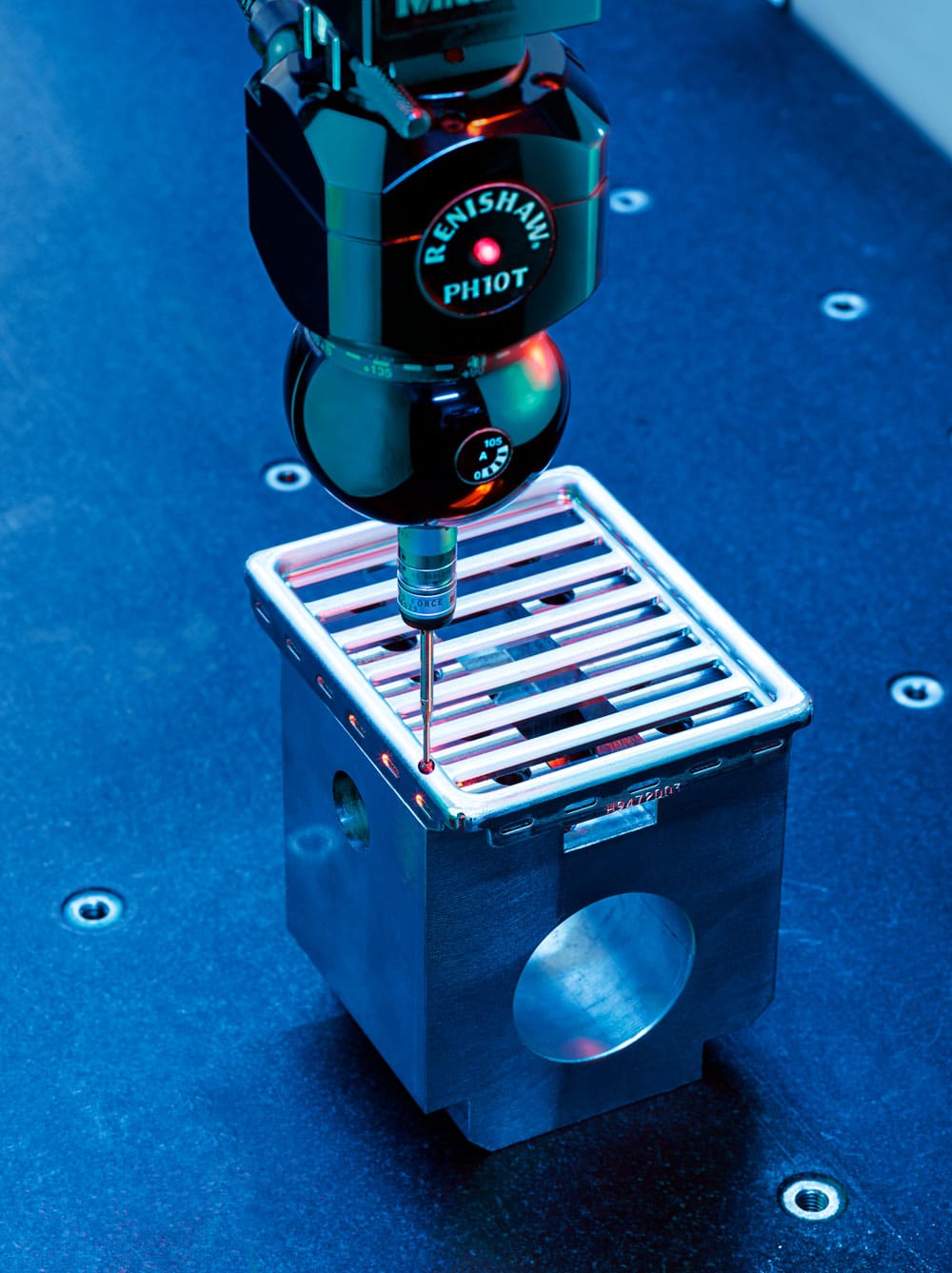

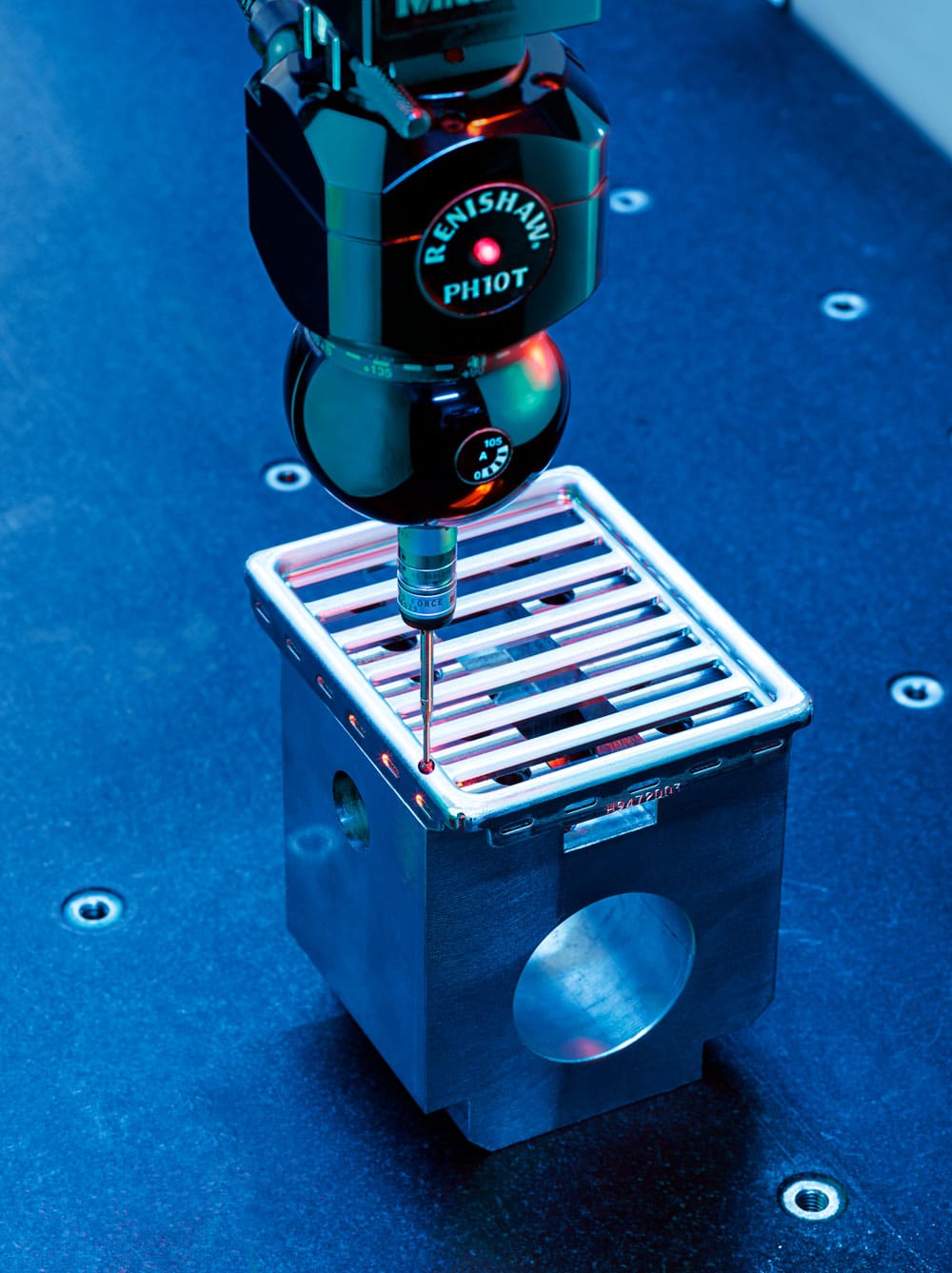

Non-destructive inspection and measurement of parts with high accuracy and repeatability of measurement and the ability to perform automated checks efficiently and effectively.

The computerised quality management system (QMS) allows us to comply with the standards based on TS16949 and ISO14001. By analysing data and identifying opportunities for improvement, we are able to control and improve processes in order to deliver high quality products and services to our customers. qualitat als nostres clients.

Non-destructive inspection and measurement of parts with high accuracy and repeatability of measurement and the ability to perform automated checks efficiently and effectively.

> Ecological Cleaning REK

> Thermic treatment

> Galvanic treatment

> Paint: epoxi and KLT

> Assembly

> Plastic overcasting

This website uses cookies so that we can offer you the best user experience possible. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website or helping our team understand which sections of the website you find most interesting and useful.

Strictly necessary cookies must always be activated so that we can save your cookie settings preferences.

If you deactivate this cookie we will not be able to save your preferences. This means that every time you visit this website you will have to activate or deactivate cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, or the most popular pages.

Leaving this cookie active allows us to improve our website.

Please enable strictly necessary cookies first so we can save your preferences!

This website uses additional cookies to improve the user experience.

You can see the cookies used in the cookie policy.

Please enable strictly necessary cookies first so we can save your preferences!

More information about our cookies policy.